ENGINEERED EXCELLENCE

AN EVOLUTIONARY STEP FOR SHAFT PRE-SINKING METHODS

Murray & Roberts Cementation’s engineering team completed its service shaft pre-sinking phase of the shaft sinking contract at De Beers’ Venetia Mine sixteen days ahead of schedule. They did this by engineering a novel Pre-Sink Gantry utilising proven technologies innovatively which streamlined the operations to an extent that it became safer, more efficient and cost effective.

The validation of the concept over two pre-sinks is such that it has added a new alternative to the way that the global industry can approach pre-sinking. The Murray & Roberts Cementation team see this success as a result of harnessing the diverse skills, knowledge and experience that is entrenched within the DNA of the

company and its people.

WHERE IT ALL BEGAN

The Venetia bid included a preferred requirement for the successful contract team to engineer a new way to execute pre-sink operations. De Beers’ key requirement was for bidders to come up with a more mechanised solution that would remove safety hazards for the sinkers without jeopardizing productivity.

A team of engineers, technical assistants and designers from Murray & Roberts Cementation conceptualised a single and dual sink shaft solution that would meet, and exceed, its clients’ needs within legislated regulations.

Murray Macnab, Global Director of Mining and Mine Development for WorleyParsons said this about the Pre-Sink Gantry and a legacy of industry initiatives: “Eliminating hazards for employees is at the centre of our efforts as we re-engineer our processes and equipment for shaft sinking. The Pre-Sink Gantry system and method has addressed most of the lessons learnt on projects in the past.”

HOW IT WORKS

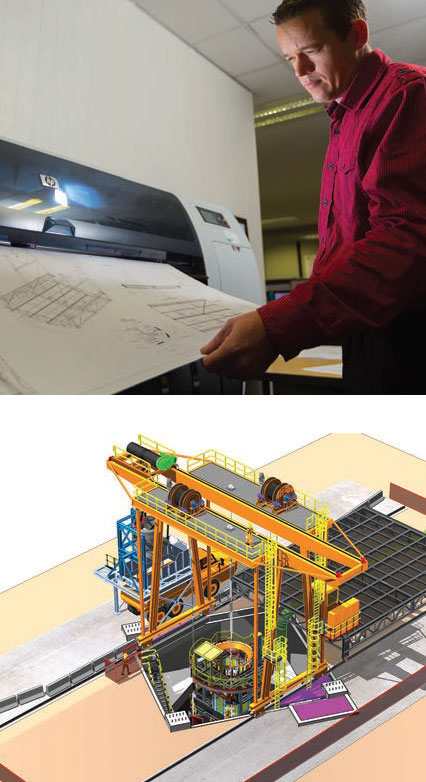

The Pre-Sink Gantry is essentially a movable gantry crane system that is able to carry and manoeuvre a movable suspended stage, together with the mucking hoist which is able to roll over and away from the shaft during pre-sinking operations.

Sounds simple but in reality this is a highly technical engineering integration of separate functions that has enabled the team to signifi cantly mitigate the risk of injury and improve productivity during pre-sink operations, especially in the case of dual shaft sinks, where set up time for the second shaft when using one suite of equipment is typically reduced from 6 weeks to 5 days.

“Murray & Roberts Cementation has developed a system that is like nothing the mining sector has seen before,” says Allan Widlake, Business Development Director for Murray & Roberts Cementation. “This type of innovation is not about the equipment, which already exists, but rather about how we put the equipment together and use institutional expertise and knowledge to develop a system that is rather special and unique.”

Because the Pre-Sink Gantry confi guration is highly integrated and operated by a multi-skilled crew, half the number of employees are needed to execute a successful pre-sink, which of course means a decrease in exposure to potential risks.

The main gantry girders were designed to accommodate the loads from the main hoist (used for kibble hoisting and stage suspension) which allows for a pre-sink of 80 metres below collar elevation as well as the stage winders (used to raise and lower the pre-sink stage).

The height of the gantry structure was matched to the height of the stage to enable the stage to clear the collar once raised to the upper limit. Once the stage has been raised in this upper position, the long travel wheel drive motors are energised to move the Pre- Sink Gantry, complete with suspended stage, away from the shaft,

drawing a blast cover over the excavation.

When in use the blast cover effectively prevents fl y rock from leaving the shaft barrel when the blast is set off. No manual intervention is required to position the blast cover, removing a labour intensive activity in an open excavation. A feature of the system is that it involves the complete removal of the stage from the shaft barrel before each blast, which substantially reduces potential structural and equipment damage.

“We stand at the threshold of an exciting and rewarding phase of development in our Group, as we strive to become a leading international engineering and construction firm, known for excellence in all that we do.”

The electronic control and data capturing system is housed in the drivers’ desk; the drivers’ cabin is positioned strategically allowing for high visibility of all shaft operations without extensive use of CCTV. Full data logging is provided for machinery, rope loads, signalling and distance status, and is accessible in real time through secure access on the internet.

“Murray & Roberts Cementation is passionate about safety and productivity improvement. As such, we are constantly searching for new innovations, methods and engineering solutions that help us to achieve this.”

“We believe the Pre-Sink Gantry is an excellent example of our global expertise, experience and knowledge coming together to create a proposition that achieves both our safety and effi ciency objectives. I am very proud of our team,” says Widlake. Because the system is able to be rapidly installed at projects, exposure to construction hazards is reduced signifi cantly. The erection is simplifi ed for safer crane lifts by hinging the gantry support legs, lifting up the main beam which has all the winders already installed. This is rather like a giraffe getting up after drinking at a waterhole.

TESTING AND TRAINING

The Pre-Sink Gantry was installed at Bentley Park, the company’s world class training academy and facility near Carltonville, where it underwent rigorous testing and validation before being transferred to Venetia.With the understanding that the unconventional nature of the new Pre-Sink methodology required a different mind-set, the team then set out to fi nd the right people for the task.

“Through a thorough selection process, we hand-picked and developed the multi-faceted skills in people that match the ‘out of the box’ thinking applied in the design of the Pre-Sink Gantry system. Our team was put through a rigourous hands on and e-Learning training programme which I believe has culminated in us developing the most advanced pre-sink skills available,” says Tim Wakefi eld, Engineering Services Executive for Murray & Roberts Cementation.