MAP – MAPPING THE PATH TO SAFETY

"The MAP programme has taken a non-traditional approach to safety management, not because these tools don’t work, but because we believe that we can do better for our people."

Thokozani Mdluli, Group Health, Safety and Environment Director

The Murray & Roberts Group has set an ambitious target of achieving Zero Harm across all its businesses and aims to provide all employees with a safe and healthy work environment.

The Stop.Think.Act 24/7 programme seeks to create a mindset and an environment where people believe it is possible to work injury free, regardless of where they are in the world, what role they undertake, or in which business they work.

The industry in which the Group operates is considered high risk, and employees on site are exposed to hazards that can cause serious injury if not properly managed. A typical site has multiple dynamic work fronts and different overlapping trades working adjacent to one another. Our safety management programmes must therefore be effective in managing change on an hourly, daily and weekly basis.

The Group has implemented a number of measures to manage safety, these include Fatal Risk Control Protocols and Life-Saving Rules.

These programmes have increased awareness around hazards and safety requirements, as evidenced by the Group’s industryleading lost time injury frequency rate of 0.79 achieved last financial year. However these measures can become normalised as employees are exposed to them on a daily basis.

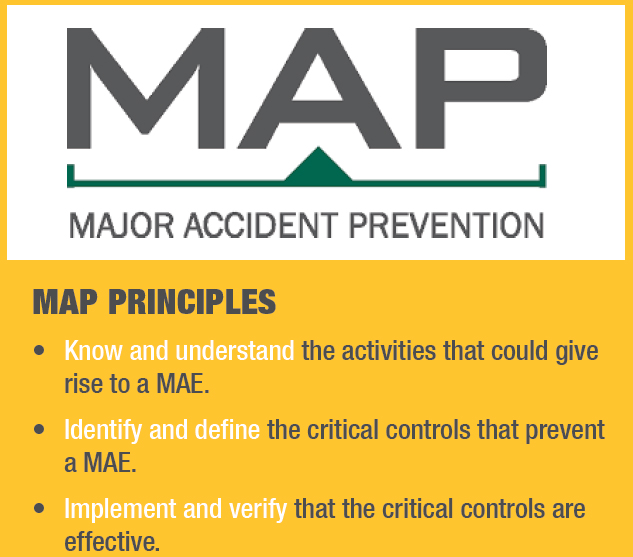

Last year, the Major Accident Prevention (“MAP”) programme was implemented to further focus interventions aimed at preventing major accidents and fatalities on our sites. MAP was developed by Clough and ensures implementation and verification of critical controls on high risk activities on site. It focuses management’s and employees’ attention on hazards and the activities which give rise to these major accidents and fatalities, and provides real time verification that the critical controls – actions taken in the field that directly prevent a Major Accident Event (“MAE”) hazard – are implemented each time employees are exposed to MAE/fatal hazards.

By engaging employees who are performing the task to actively check on and implement the critical controls, employees and line management proactively intervene and prevent major accidents from occurring. Leaders managing high risk activities are empowered and have a clear mandate to ‘stop work’ when they identify a MAE critical control that is not being implemented or effective. Lessons learnt from safety incidents and MAP field implementation are reviewed and incorporated back into the MAE

register for deployment and verification on site.

The MAP programme produced impressive safety results on Clough’s Ichthys and AP5 projects with an immediate reduction in high potential incidents, this continued with the Oil & Gas business platform achieving a record 11 lost time injury-free months late last year, following the MAP programme implementation.